Heat Affected Zone (HAZ) in Welded Joints – Causes, Effects & Control

20th July 2022

Shalini Ghose

Shalini Ghose

What is Heat Affected Zone?

Heat Affected Zone (HAZ) is an area of a metal workpiece which has been subjected to microstructural changes due to exposure to high working temperature in solid state. Heat affected zone is usually caused by welding or cutting under high temperatures. It is the zone which appears between a weld or cut and the unaffected part of the workpiece.

As welding takes place, the area directly adjacent the welding area is also heated to a temperature close to its melting temperature. As the weld pool moves further away, this heated area may experience a quick drop in temperature leading to the occurrence of thermal treatment. This thermal treatment causes this area to possess a different microstructure and properties to that of the parent material. This area is called the Heat Affected Zone.

If the base material undergoing welding is steel, when this area undergoes a quick rise and fall in temperature, it can lead to the formation of martensite or other properties which are susceptible to cracking or corrosion. People often ask; why do most welding failures occur in the heat affected zone? It is because HAZ possess the weakest sections of a structure.

In a HAZ, different areas are formed by different temperatures, and this happen as heat dissipate further away from the welding or cutting region. As heat affected zone is formed, it creates different colours along the area called temper colours. These different colours, also termed heat tint, represent the approximate amounts of temperatures attained by the various areas of the HAZ. If we consider the welding of AISI 304 stainless steel in the fields, the derivable colour bands and related temperatures are shown below:

| Colour | Temperature |

|---|---|

| Light yellow | 290˚C / 550˚F |

| Straw yellow | 340˚C / 640˚F |

| Yellow | 370˚C / 700˚F |

| Brown | 390˚C / 735˚F |

| Purple brown | 420˚C / 790˚F |

| Dark purple | 450˚C / 840˚F |

| Blue | 540˚C / 1000˚F |

| Dark blue | 600˚C / 1110˚F |

The formation of heat tint can be influenced by some factors. When the surface of the workpiece is rough, there is quicker oxidation leading to more defined colour formation. Surface contamination also affects the formation of heat tint, when there is presence of impurities such as oil or paints, heat tint can be affected but not the HAZ.

Additionally, when there is less oxidation, heat tint may not be well defined. This can occur when welding is performed with electrodes that produce protective gases which cover the weld surface. Also, when the steel contains high chromium, the heat tint tends to reduce because chromium reduces oxidation.

Heat Affected Zone Diagram

Image credit: Keyence

What are the Causes of Heat Affected Zone?

The formation of heat affected zones can be influenced by several factors such as:

- Nature of material: When the base metal has high thermal diffusivity, the area close to the weld easily loses heat thereby reducing the formation of HAZ. However, when the material has low thermal diffusivity, the area close to the weld hold unto the heat longer, leading to the formation of wider HAZ.

- Cutting: When a material is undergoing high-temperature cutting, its shear strength has to be overcome and this leads to the production of heat which can give rise to HAZ.

- Welding speed: Slower welding speeds give rise to more HAZ.

- High heat input in welding: When the heat input during welding is too high, there tend to be greater area of HAZ.

- Geometry of the base metal.

- Electron beam welding and laser welding produce slim HAZ due to heat concentration is a little space.

Effect of Heat Affected Zone in Welding

HAZ is a serious metallurgical problem, therefore every welding professional should be aware of the dangers it poses. Common effects of HAZ are listed below:

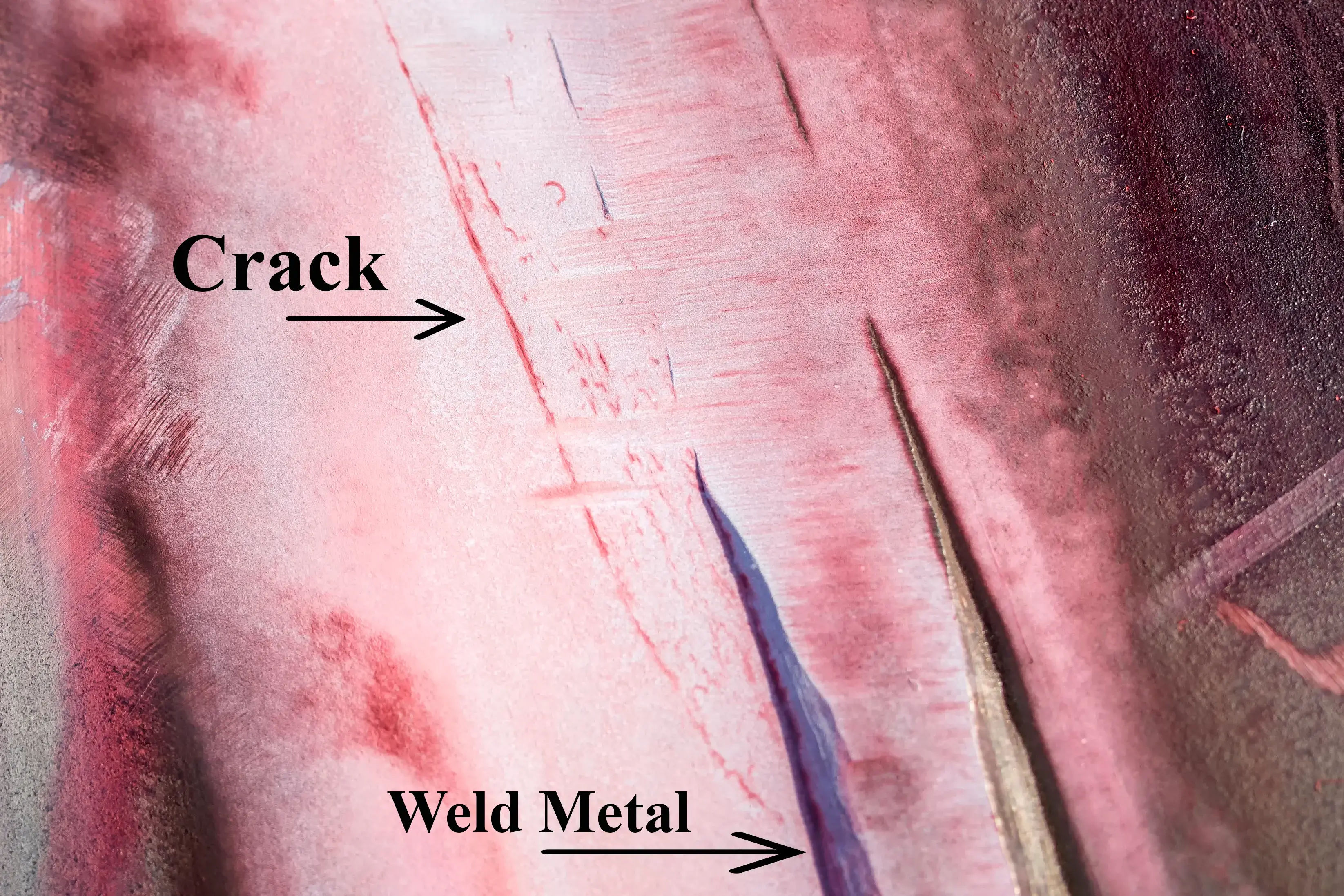

Heat affected zone cracking: Due to change in the mechanical properties and microstructure of HAZ, they lose ductility and toughness which make them more susceptible to stress cracking during operation.

Heat affected zone failure: Failure of HAZ can arise due to factors like hydrogen embrittlement. Hydrogen embrittlement occurs when hydrogen atoms diffuse into the metal grain boundaries at high temperatures which reduce the tensile strength of the heat affected zone.

Corrosion in heat affected zone: When working with stainless steel, high temperature in the HAZ causes the loss of chromium carbide. This causes the stainless steel to lose the ability of self-passivation which leads to intergranular corrosion. In most cases, this area loses its texture and appearance and turns black in colour.

Change in phase: From the iron phase diagram, steel phases like austenite can degenerate into martensite due to exposure to high temperatures followed by rapid cooling. This martensitic steel is metastable, harder and more brittle than the parent steel. Martensitic HAZ are very likely to fail in service.

How to Reduce Heat Affected Zone in Welding

Heat affected zone is an unwanted occurrence in welding operation. But it is impossible to completely avoid HAZ; however it can be mitigated and reduced after welding.

High welding speed: It is recommended to increase welding speed during welding operations. This is because slow welding speed leads to the formation of larger weld beads which leads to the retention of more heat, causing wider HAZ as a result.

Post-weld heat treatment: After welding operation, the HAZ can be thermally treated to alter the phase and restore majority of its mechanical properties. Solution annealing is a method of post-weld treatment which involves heating the steel to a specific temperature and holding for some time to allow microstructural changes to occur and restore the original properties of the steel.

Mechanical finishing: This involves the use of mechanical actions such as sandpapering to eliminate heat tints formed by surface oxidation; the resulting layer is a self-passivation stainless steel. Machining is the most effective means of getting rid of HAZ, however this could weaken the workpiece due to loss of material.

Conclusion

The formation of heat affected zone in welding operations is an undesirable yet unavoidable occurrence. Most failures of welded parts occur at the heat affected zones due to their overall weaknesses. This is why most industries employ professional welders who can complete certain welding operations at a desired speed which greatly narrows the HAZ.

Thermally treating the welded region can also help to mitigate the effect of HAZ, restoring majority of the lost mechanical properties. It is important that most people understand the concept of heat affected zone and the negative impacts it can have in welded structures, thereby taking it seriously and applying every precaution to ensure it is always mitigated.

High welding speed: It is recommended to increase welding speed during welding operations. This is because slow welding speed leads to the formation of larger weld beads which leads to the retention of more heat, causing wider HAZ as a result.

Post-weld heat treatment: After welding operation, the HAZ can be thermally treated to alter the phase and restore majority of its mechanical properties. Solution annealing is a method of post-weld treatment which involves heating the steel to a specific temperature and holding for some time to allow microstructural changes to occur and restore the original properties of the steel.

Mechanical finishing: This involves the use of mechanical actions such as sandpapering to eliminate heat tints formed by surface oxidation; the resulting layer is a self-passivation stainless steel. Machining is the most effective means of getting rid of HAZ, however this could weaken the workpiece due to loss of material.

Thermally treating the welded region can also help to mitigate the effect of HAZ, restoring majority of the lost mechanical properties. It is important that most people understand the concept of heat affected zone and the negative impacts it can have in welded structures, thereby taking it seriously and applying every precaution to ensure it is always mitigated.